Photo: Tesla

Tesla continues recruiting for positions related to battery manufacturing at Giga Berlin and Giga Texas. This is further evidence that Tesla continues to advance its goals of vertically integrating the major components of its vehicles and energy storage lineup. And the battery, of course, is one of the company’s most critical components.

During the Q2 2020 Earnings Call, Tesla CEO Elon Musk confirmed that the company's original plan remains in place, and Giga Berlin will manufacture its own battery cells to match vehicle assembly volume. Giga Texas will also build its own battery factory. According to Tesla, the goal is to locally produce the batteries needed for the car factories.

Several months ago, Tesla opened recruiting in Germany and the USA for its new factories for positions related to the production of battery cells. Today the company reiterated that it needs qualified specialists to help it achieve its goal of producing advanced batteries, and drew attention to the list of existing positions.

In the job descriptions, Tesla points out that the company's cell manufacturing engineering group is looking for highly-motivated professionals to accelerate their next-generation battery cell manufacturing program:

Engineering

Cells are optimized electrochemical, thermal, micron-scale mechanical systems designed to be manufactured at millions per day scale. Engineer the future of cell technology for energy and vehicle applications at Tesla's state-of-the-art, in-house prototyping, validation and manufacturing facilities.

Manufacturing

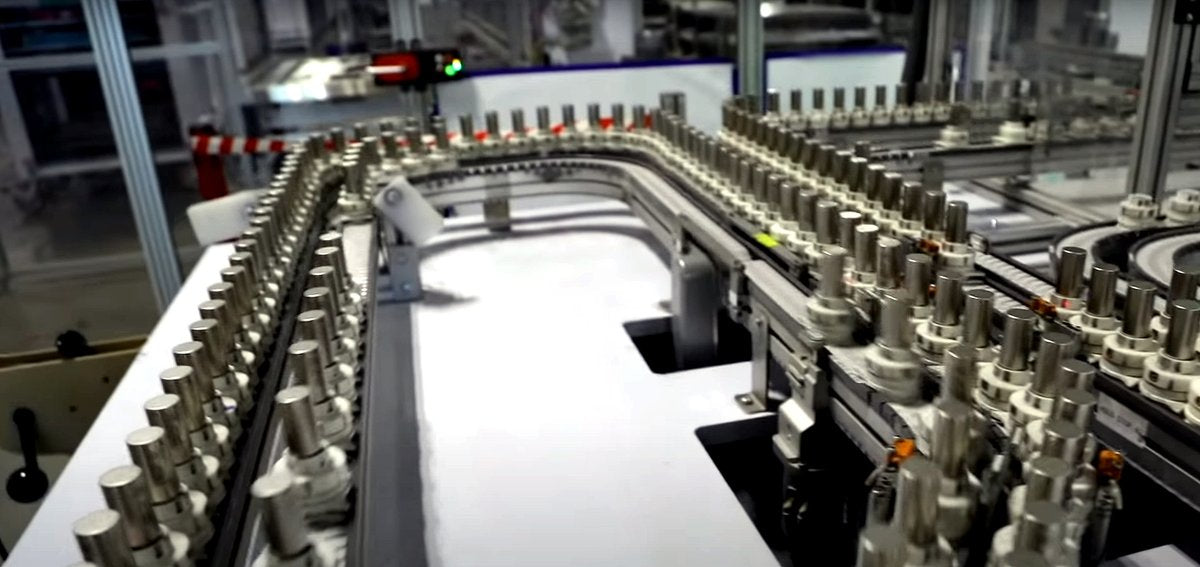

With cells, designing and ramping the manufacturing system is more than 90 percent of the challenge. Tesla offers to help it achieve terawatt-hour-scale by rethinking manufacturing processes and equipment together with its in-house equipment design and fabrication teams.

Materials

Successfully scaling cell active materials requires rethinking how the company processes them — from their original source in-ground or in recycled products to the final cell anode and cathode. Future Terafactories will process hundreds of metrics tonnes of active material every hour; so any energy, material, or efficiency wins will lead to massive dividends. Tesla invites you to join their effort to dramatically improve lithium and cathode processing while scaling low-cost, energy-dense silicon in the anodes.

Equipment

Build the next electrode and cell machines in Tesla Terafactories. Design and implement the best high-speed, continuous-motion, precision-manufacturing equipment in the world in a tight-feedback loop with product and manufacturing teams.

Operations

Cell factories demand precision in materials, machines, facilities, and execution to build cells at the highest quantity and quality. Drive the build-out of new factories and products from concept through design, install, integration, ramp and mass production.

Come work on cell / battery production at Giga Texas & Giga Berlin! https://t.co/PhsI5bb0uD pic.twitter.com/jEUatMLDmE

— Tesla (@Tesla) January 17, 2021

© 2021, Eva Fox. All rights reserved.

_____________________________

We appreciate your readership! Please share your thoughts in the comment section below.

Article edited by @SmokeyShorts, you can follow him on Twitter