Image: Tesla patent

Tesla significantly outperforms competitors as it invests heavily in the development of technologies for production. It is reported that, in the future, the company intends to use the 12,000-ton Giga Press to cast car bodies in one piece.

Recently, Alex Avoigt/Twitter visited Giga Berlin during the County Fair and had the opportunity to communicate with a few Tesla managers, and, accordingly, learn from them a lot of information about Giga Presses. In addition, Alex was contacted by an industry insider who gave him information on casting machines in general and about Tesla's Giga Presses. He presents the insider as a truly reliable source who is trustworthy. In his new video, Alex shared all the information he has, and there really is something interesting.

Tesla is currently using two types of 6,000-ton Giga Presses to cast the one-piece rear end of the car and the one-piece front end of the car. At the moment, this production technology is used only for the production of Model Y. And at first, the casting of the front part will only take place at Giga Berlin and Giga Texas, while the casting of the rear part is already taking place at Giga Shanghai and Fremont. Giga Texas has already started testing the Giga Press for the front end casting to be fully ready when production starts.

Another type of Giga Press with a clamping force of 8,000 tons will be used for the rear part casting of another Tesla vehicle—the coveted Cybertruck. During the Q4 2020 Earnings Call, the company's CEO Elon Musk mentioned that Tesla intends to use a similar Giga Press as for the Model Y, but the clamping force for producing the rear part of Cybertruck will be 8,000 tons. According to information from Alex, this machine is already at the production stage.

Now, according to Alex's source, IDRA's China KL are developing a machine with a clamping force of 12,000 tons, which is designed to cast the entire body (frame) in one piece. With such a machine, the production of the body can be much faster and easier. According to information from the source, the production in this machine can reduce the time spent on car production by 25%. In addition, a 10% reduction in downtime is expected.

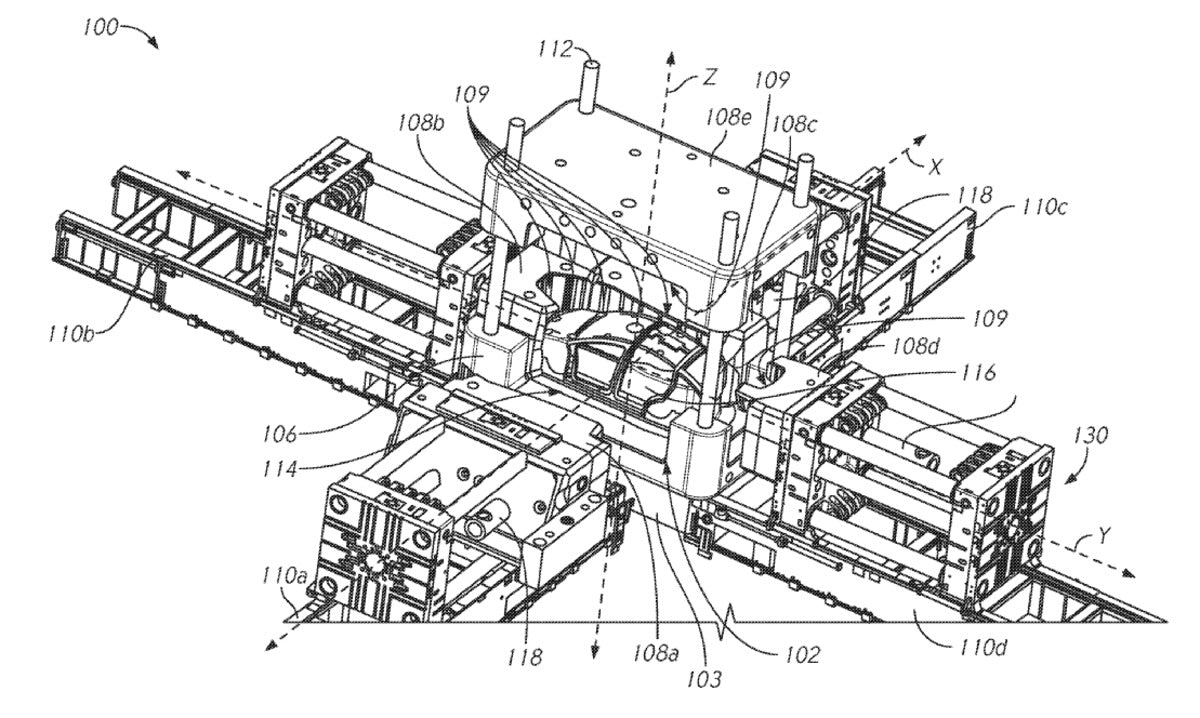

In 2018, Tesla filed a patent for “Multi-Directional Unibody Casting Machine for a Vehicle Frame and Associated Methods,” which discloses a new casting machine that Tesla plans to use for casting bodies in one piece. As described, such casting machines may reduce a number of casting machines or actual castings required to cast a complete or substantially complete vehicle frame.

This approach completely coincides with Musk’s idea of how he would like to see the production of Tesla’s cars. Using the huge Giga Press, the process of making cars in the manufacturer's factories can be as easy as making toy cars.

With our giant casting machines, we are literally trying to make full-size cars in the same way that toy cars are made

— Elon Musk (@elonmusk) January 18, 2021

© 2021, Eva Fox | Tesmanian. All rights reserved.

_____________________________

We appreciate your readership! Please share your thoughts in the comment section below.

Article edited by @SmokeyShorts, you can follow him on Twitter